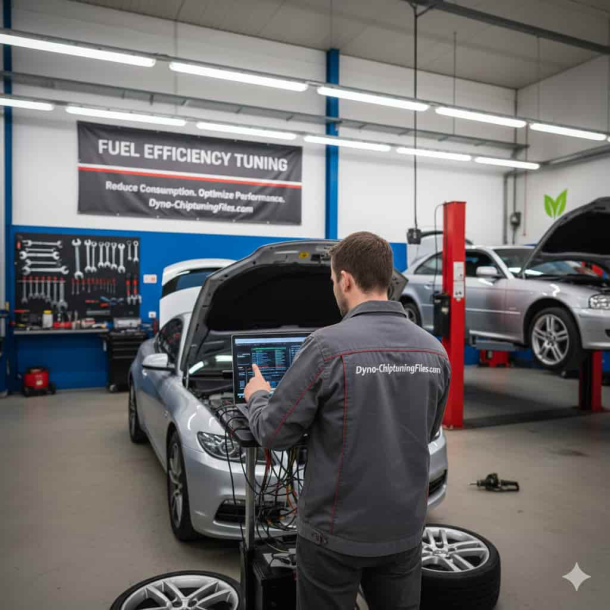

Fuel tuning and how it helps improve efficiency

This article explains how fuel tuning works and how precise calibration can improve efficiency without compromising reliability. It shows how professional fuel adjustments optimize combustion, drivability, and real-world fuel consumption.

In this article

For professional tuners and workshops fuel consumption is no longer just a customer complaint topic. It is a clear technical target alongside power drivability and reliability. Modern engine management systems offer significant scope to optimise fuel efficiency when calibration is handled in a structured way. This is where fuel tuning becomes a precise tool rather than a vague promise.

We develop and validates calibrations daily on a chassis dynamometer and in real world conditions. That experience shows that fuel tuning is not about making a single fuel map leaner. It is about managing the complete combustion process torque structure and air fuel control so that the engine produces the requested torque with as little fuel as reasonably possible.

What fuel tuning actually is

Fuel tuning is the process of optimising the fuel related parts of an engine control calibration in order to achieve defined goals such as reduced consumption improved response or a different power curve.

In practice fuel tuning does not stand alone. It is closely linked to:

-

Torque request and torque limitation maps

-

Boost pressure and air mass control

-

Injection timing and pressure

-

Lambda targets and exhaust temperature protection

From a calibration perspective the question what is fuel tuning is therefore best answered as follows. Fuel tuning is the coordinated adjustment of fuel quantity fuel timing and mixture targets within the overall torque structure of the engine. The objective is to maintain or improve drivability while reducing specific fuel consumption and respecting mechanical and thermal limits.

Can you tune specifically for fuel efficiency

Yes it is possible to tune specifically for fuel efficiency and for many engines there is measurable potential. The realistic gain depends on engine type fuel quality original calibration strategy and driving profile.

Fuel efficiency tuning by Dyno-ChiptuningFiles.com typically focuses on

-

Reducing unnecessary enrichment in part load areas

-

Aligning torque request with the most efficient operating zones of the engine

-

Optimising boost and air mass so that pumping losses are reduced

-

Refining injection timing to improve combustion efficiency and cold running

The target is not simply to run lean everywhere. That would cause drivability issues and in some cases increase emissions or component stress. Instead the calibration is shaped so that in common daily driving the engine spends more time in zones with a lower brake specific fuel consumption.

For professional workshops this means you can answer the customer question can you tune for fuel efficiency with a technically grounded yes provided the vehicle and usage pattern are suitable and expectations are realistic.

How fuel tuning improves real world efficiency

Improved fuel efficiency is realised in the operating regions where the vehicle spends most of its time. For daily driven cars this is usually light to medium load at moderate engine speeds.

A well developed efficiency tune can for example:

-

Reduce the fuel needed to maintain a given cruising speed

-

Improve low to mid range torque so the driver can use higher gears sooner

-

Smooth the response so that small throttle changes do not trigger unnecessary enrichment

On the dyno this is visible as a reduced fuel flow for the same wheel torque in these areas. On the road customers often report fewer required gear changes and lower indicated consumption for the same journeys.

We validate such calibrations by combining dyno steady state measurements with logged road tests. This confirms that theoretical efficiency gains are actually accessible in real traffic rather than only under laboratory conditions.

How to improve fuel efficiency from a calibration point of view

When a workshop asks how can I improve my fuel efficiency the answer is a combination of calibration and practical advice. From the ECU side several areas are key.

First the torque structure must be coherent. Requested torque pedal maps and limitation maps have to work together. If torque requests are excessive the engine will operate in regions that are not efficient even if the air fuel ratio looks acceptable in the logged data.

Second the air path must be efficient. Correct boost targets and air mass control reduce pumping losses. This is particularly important in turbocharged engines where unnecessary high boost at low load increases fuel consumption without a corresponding gain in torque.

Third injection timing and pressure need to be matched to the chosen torque and boost targets. Properly phased combustion can deliver the same torque with less fuel and lower exhaust temperatures which also benefits component life.

Dyno-ChiptuningFiles addresses these elements as a whole rather than changing a single map in isolation. That system approach is essential if you want a result that is efficient stable and repeatable across different ambient conditions.

The role of the driver and the workshop

Even the best efficiency oriented calibration cannot fully compensate for aggressive driving or poorly maintained hardware. For a realistic outcome workshops should combine fuel tuning with clear communication and basic checks.

Important workshop controlled factors are:

-

Correct tyre pressures and wheel alignment

-

Clean air filter and properly functioning sensors

-

Absence of dragging brakes or other mechanical losses

On the driver side behaviour remains decisive. Smooth acceleration anticipatory driving and intelligent use of gears allow the calibrated efficiency benefits to show in daily use. When drivers are informed that their vehicle has an efficiency tune they are more likely to adapt their style accordingly which further supports the result.

Why fuel efficiency projects benefit from Dyno Chiptuning

Fuel tuning for efficiency demands the same level of expertise as high power performance work. In some cases it is even more demanding because the changes are subtle and must remain transparent to the driver.

We support professional tuners and workshops by:

-

Using experienced and certified calibrators with a strong background in torque structure and emissions control

-

Developing efficiency oriented base calibrations on the dyno with careful monitoring of exhaust temperature and combustion behaviour

-

Offering consistent files that match the correct software version and reading method so that your workflow remains predictable

This allows workshops to position fuel efficiency tuning as a serious technical service rather than a vague add on.

Fuel tuning is the structured optimisation of the fuel related parts of an engine control calibration within the wider torque and air management strategy. You can indeed tune for fuel efficiency provided that the work is carried out with a clear concept realistic targets and respect for hardware limits.

To improve fuel efficiency in a meaningful way you need both a well developed calibration and a professional approach in the workshop and on the road. By working with our tuning file service you gain access to calibrated and tested files that support lower consumption without sacrificing drivability or reliability giving your customers a measurable and technically credible benefit.